Basic Tenets of a Water Brake Dynamometer Operation

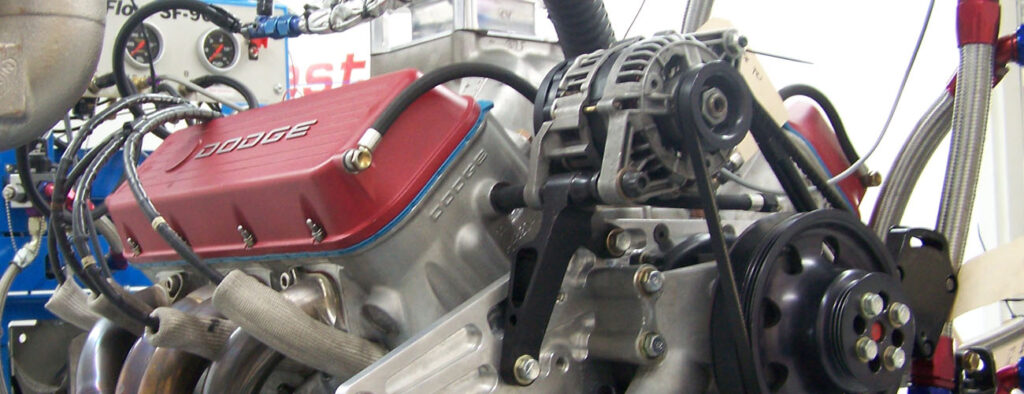

An engine dynamometer (dyno) is a servicing instrument that enables the operator to load an engine with a regulated load safely. The only way to validate the engine’s capabilities is through a loaded engine test. A dyno allows for optimal operation of an engine across its power range without putting it into service. Defects in the assembly process can be identified before the engine is mounted in the chassis, and an actual evaluation of the engine’s operational condition can be conducted. The dynamometer is the final quality control check before installing an engine.

A dynamometer is composed of two primary components:

- The absorption unit

- Torque indication system

A water brake dynamometer employs an absorption unit (absorber) to absorb energy via momentum exchange, with water serving as the working fluid. A water brake absorber comprises at least two stators and one or more shaft-mounted rotors (or end bells). The rotors spin freely inside the absorber housing in the absence of water. When water is injected into the absorber, it is accelerated by the rotating rotor and “thrown” into the stators. The stators would also begin to rotate without restraint, like a torque converter. However, the stators are restricted by a torque arm coupled to a load cell.

The load cell determines the force required to rotate the stators. If you know the distance between the absorber’s axis and the torque arm, you can determine how much torque there is.

Concerning Horsepower

If we measure speed, we may calculate horsepower using the following formula: (T x rpm)/5252 = HP.

Load absorption is proportional to the volume of water contained within the absorber housing. Because the water eventually absorbs all the horsepower in the form of heat, it must be drained and replaced with cold water to avoid boiling. By limiting the exhaust and controlling the flow of water through the absorber, it is possible to control the amount of water inside and thus the load.