Why Dyno Testing is a Smart Move and Facts to Know Before Testing

Many hot rodders who don’t have a lot of money would rather not spend $1000 on dyno testing for a day than buy new cylinder heads instead. But a different point of view should be looked at. There is no point in having good heads on an engine that is no good. The goal should be to get the most from the parts in your engine now and increase the horsepower of the engine at the same time.

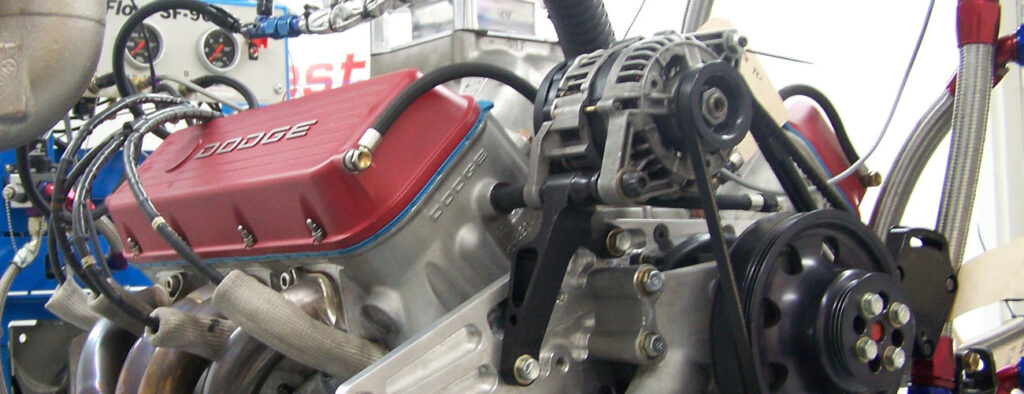

Usually, people think that engine dyno testing is a must for race teams and maybe even a luxury for rich people who own many cars. However, the benefits of a modified street or race engine, especially today’s EFI engines, are clear for most home projects. An engine can be properly broken in for a half-day, and the timing and jetting can be set for the gasoline it will be using. Or it can take several days to try out different parts and tune-ups. You could see a 40 plus horsepower difference just because you tuned your car well.

Camshafts, carbs, and header pipes are all things that more adventurous people might play around with. Any problems found during the tests will be easier to fix on a dyno stand than under the hood. Testing and tuning an engine on the dyno are also cheaper in the long run than at the track.

Another argument for dyno testing before track testing is as follows.

Ask yourself how much it will cost you for fuel, tires, food for your crew, towing, and track fees. A full day of testing at the track may not have led you to the right answer. You can adjust the engine, get the right converter, and figure out where the shift points should be on the dyno.

In many parts of the country, auto repair shops and high-performance shops install engine dynos, which gives customers a choice. Although a dyno cell costs a lot of money, it’s still a lot of money for customers. They start at $250 for a half-day and go up to $1,500 for a full day. The price for a full day of work on a carbureted Chevy V-8 is usually between $500 and $700. For non-Chevy cars, some shops charge more. This is because it takes longer and costs more to hook up. In addition, an EFI (forced induction) engine needs a more skilled person to run a dyno. This means that the appointment may also be more expensive.

When planning a dyno test, the first thing to do is find a good dyno operator. Ask your friends or talk to people who race at the track. Ask about the dyno’s equipment and how often it’s calibrated or checked when you choose a shop. If the dyno cell is messy and greasy, likely, the dyno doesn’t get a lot of attention. A messy workbench may signify that you aren’t very organized, and it takes a lot of time to pull things out between pulls. On the other hand, an accurate dyno cell has good ventilation, a lot of clean air, and the right way to route the exhaust.

Preparation and planning are the keys to a successful day on the dyno.

Work with the operator to set a realistic timetable and figure out who brings what to the party. It’s common for people to ask about the water pump and the distributor. The starter, bell housing, flywheel or flexplate, water pump, and fuel are common. The customer should have their engine as close to done as possible. If the customer has their fuel regulator, some shops prefer to use it to match what’s going on in their cars. If you use different fuels for street and strip action, you should bring some extra.

Headers and exhaust should also be discussed.

Customers may not be able to use Dyno headers if the shop doesn’t have a set that fits their car’s size and length. One common solution is to make custom header plates that hold the EGT sensors and can be used with other headers. Another way is to run a full day of tests with the dyno headers and then install the customer’s tubes to see if there is a difference in how the tubes work. However, EFI, dry sump, and turbo/supercharged engines need more help setting goals, planning the day, and ensuring the right tools are available.

A basic test session will help you figure out ignition timing, carb jetting, and valve lash and look for leaks and trouble spots. Changing carbs might be a good idea if the dyno operator thinks the carburetor, isn’t the right size. The person who runs the dyno may also suggest a carb spacer. A belt drive or two-piece timing cover will help speed up changing the cams.

Cams should work. You don’t want to put in a second cam for the first time and find out that the pistons and valves don’t fit together well. Do this before you put your car on the dyno. Make a mock-up of all the cams. It also helps if you know how to level a cam.

Testing procedures vary between dyno operators.

A step test is better for some people because the engine rpm stays the same while recording the data. When the computer runs the engine through its rpm range and collects data at different speeds, most people like this type of test better. Many people go at 300 rpm per second, but some circle-track customers go slower, and drag racers with a lot of power go higher. Customers should learn about the different tests and types of data that the dyno acquisition software will record before using it. Each time you run a dyno, you can get 8 to 10 pages of data.

The greatest single waste of time on dyno day is trying to analyze all the data on-site.

Before you start:

- Make a plan and keep good records of your changes.

- Take carbs, throw jets at it, take them away, and see what the net is in general terms.

- Move on to the next test.

This is how it works:

It will be less powerful if you tune your car by looking at the spark plugs and the numbers on the engine. So you tune your car to get the best overall power curve, then look at the plugs and know that’s what you want to do at the track.

It’s unlikely a dyno test will hurt a properly built engine.

Most shops have dyno mules that can run for a long time before they break or need to be rebuilt. Modern dynos are made to finish the tests quickly and have safety systems that can tell you if there isn’t enough oil pressure.

Dyno operators are now using high-tech data acquisition and simulation software to speed up the testing or get more precise information for research that will be done later. Many dyno shops have programs to predict how well a car will do on the track by looking at airflow in the cylinder head and exhaust. They can use this information to analyze the car’s overall performance. With the help of the exhaust software, dyno operators can cut or lengthen the header collectors to get 2 or 3 more horsepower.

A positive wave can sometimes be seen coming from the overlap between the air turbine specs while you are testing. They’ll start by trying to find a good spot with the headers. They’ll then make some pulls and play with the cam if needed.

Dyno operators will also add O2 sensors to each header pipe, not just the collector, to see how the fuel is distributed. This test is very useful for Quadrajets or ThermoQuad carburetors with big secondaries.

Speed and fuel distribution are very different from the front to the back of the carb. When they played around with epoxy and air dams in the intake, they saw a 27-hp boost. So, you can get a lot of great information from a dyno. It’s a great high-performance tool. People use it in different ways.